The Ultimate Guide to Choosing the Best Gas Line Crimping Tool for Your Projects

When it comes to ensuring the integrity and safety of gas line installations, selecting the right gas line crimping tool is crucial. According to a recent industry report by the American Gas Association, improper installation and maintenance of gas lines result in approximately 22% of gas-related incidents, underscoring the importance of using high-quality tools for crimping connections.

With various options available on the market, informed decisions can greatly influence the efficiency and longevity of your gas line projects. This guide aims to equip both professionals and DIY enthusiasts with the necessary knowledge to choose the best gas line crimping tool that not only meets the specific requirements of their tasks but also adheres to industry standards and safety protocols. By understanding the features, benefits, and proper usage of these tools, you can ensure optimal performance and safety in your gas line applications.

With various options available on the market, informed decisions can greatly influence the efficiency and longevity of your gas line projects. This guide aims to equip both professionals and DIY enthusiasts with the necessary knowledge to choose the best gas line crimping tool that not only meets the specific requirements of their tasks but also adheres to industry standards and safety protocols. By understanding the features, benefits, and proper usage of these tools, you can ensure optimal performance and safety in your gas line applications.

Understanding the Importance of a Quality Gas Line Crimping Tool in Safe Installations

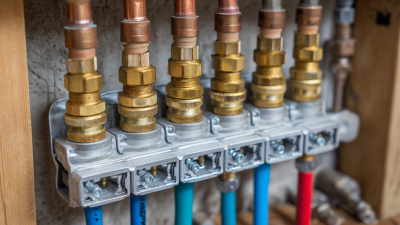

When it comes to the safe installation of gas lines, the choice of crimping tool plays a crucial role. A high-quality gas line crimping tool ensures proper fittings and secure connections, significantly reducing the risk of gas leaks. According to a report by the National Fire Protection Association (NFPA), improper installation of gas lines is one of the leading causes of gas-related incidents. Therefore, investing in a reliable crimping tool not only enhances safety but also extends the lifespan of the installation.

Moreover, a quality crimping tool delivers precision and efficiency, essential for any successful gas line project. Tools that adhere to industry standards and certifications, such as those from the American Society of Mechanical Engineers (ASME), are proven to enhance the integrity of gas line systems. For instance, it has been shown that tools with a proper crimping mechanism can reduce installation errors by up to 30%, ensuring that each connection can withstand the pressure and environmental factors that gas lines typically encounter. This not only safeguards against potential hazards but also boosts overall operational efficiency.

The Importance of Quality Gas Line Crimping Tools

Key Features to Look for in a High-Performance Gas Line Crimping Tool

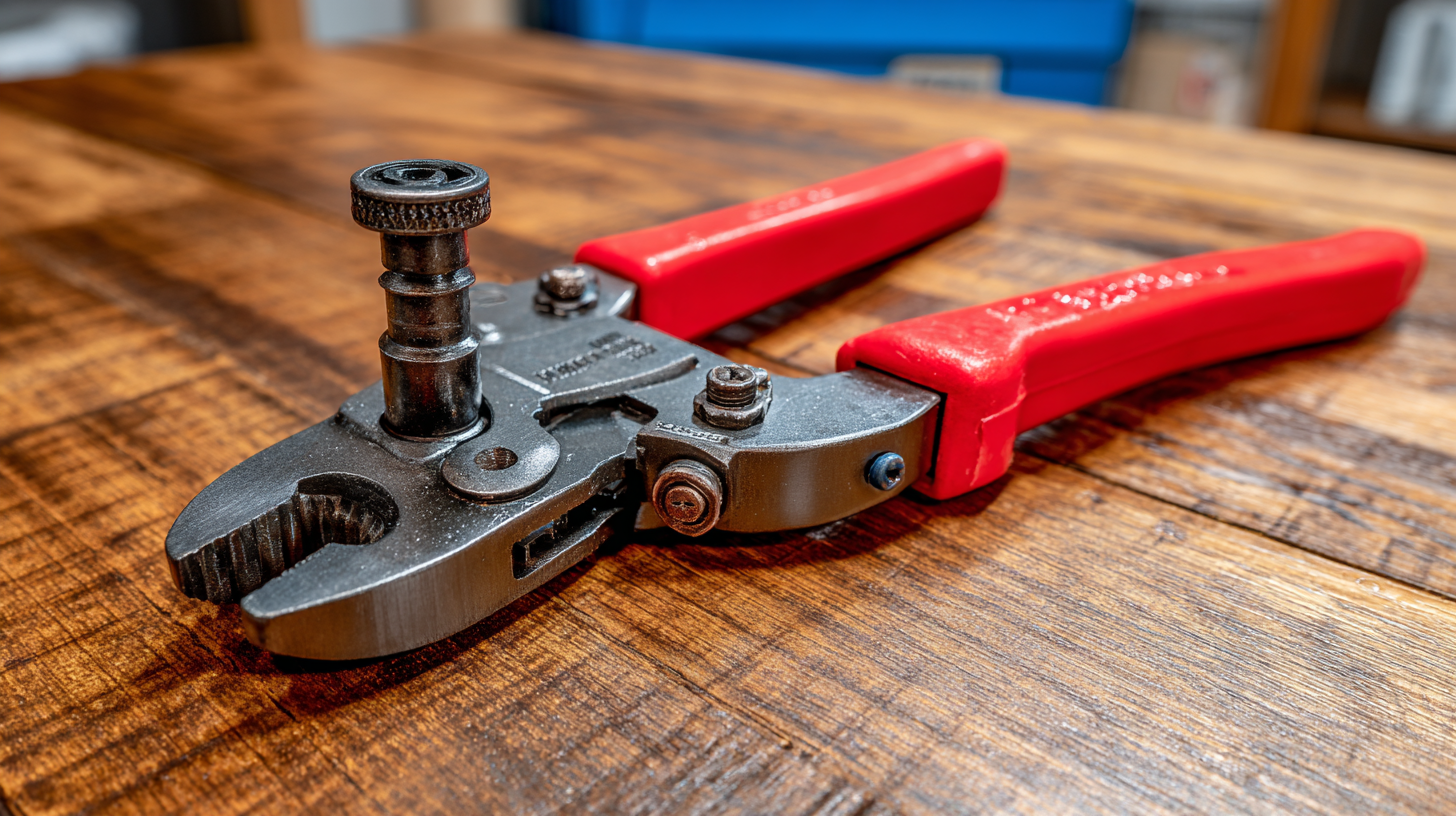

When selecting a high-performance gas line crimping tool, there are several key features to consider that can significantly impact your project's efficiency and success. One of the primary aspects is the tool’s crimping capacity, which determines the range of fitting sizes it can accommodate. A versatile tool can handle various diameters and materials, allowing for greater flexibility during your projects. Additionally, look for a tool with a robust construction, as durability will ensure it withstands the demands of regular use in diverse environments.

Another critical feature is the ease of use, including ergonomic design and intuitive operation. Tools designed with comfort in mind can reduce user fatigue, particularly during prolonged use, and contribute to more precise crimping. Moreover, the incorporation of advanced technology, such as self-adjusting mechanisms or built-in measurement guides, can enhance accuracy and efficiency, ultimately saving you time and elevating the quality of your work. By prioritizing these features, you can choose the best gas line crimping tool that meets your needs and elevates your project outcomes.

The Ultimate Guide to Choosing the Best Gas Line Crimping Tool for Your Projects

| Feature | Description | Importance |

|---|---|---|

| Material | Durable steel construction for long-lasting performance | High |

| Crimping Capacity | Suitable for various gas line sizes and types | High |

| Ease of Use | Ergonomic design that minimizes user fatigue | Medium |

| Portability | Lightweight and easy to carry for fieldwork | Medium |

| Safety Features | Built-in safety mechanisms to prevent accidents | High |

| Warranty | Manufacturer's warranty for peace of mind | Medium |

Comparison of Manual vs. Hydraulic Gas Line Crimping Tools: Which is Right for Your Project?

When choosing between manual and hydraulic gas line crimping tools, understanding the specific needs of your project is crucial. Manual crimping tools are often lighter and more portable, making them ideal for smaller jobs or fieldwork. They require physical effort and can be time-consuming, but they allow for greater control over the crimping process in tight spaces. Conversely, hydraulic crimping tools apply significant force with minimal effort, making them suitable for larger projects or repeated tasks. Their efficiency can significantly reduce the time taken on extensive crimping jobs, providing a consistent and reliable result.

Tips: If you opt for a manual tool, always ensure you have adequate training on proper techniques to avoid damaging the fittings. Additionally, maintain your equipment regularly to ensure its longevity and effectiveness. For hydraulic tools, check the hydraulic fluid levels often and inspect hoses for any signs of wear and tear to prevent accidents on the job.

Ultimately, the decision between manual and hydraulic tools hinges on the scale and type of your project. Assess the frequency of use and intended application before making your choice to ensure you select the best tool for your specific needs. Consider investing in both types if your projects vary widely to cover all potential scenarios effectively.

Evaluating Industry Standards and Certifications for Gas Line Crimping Tools

When selecting a gas line crimping tool, it is essential to consider industry standards and certifications to ensure safety and reliability. Various organizations, such as the American National Standards Institute (ANSI) and the National Fire Protection Association (NFPA), outline specifications that tools must meet to be deemed safe for use in gas line applications. These standards typically include tests for durability, performance under pressure, and resistance to wear and corrosion.

Certification marks from recognized entities, such as Underwriters Laboratories (UL) and the Canadian Standards Association (CSA), provide reassurance that a crimping tool has undergone rigorous testing and meets essential safety guidelines. Manufacturers who comply with these standards demonstrate a commitment to producing high-quality tools capable of withstanding the demands of gas line installation and maintenance. Therefore, checking for these certifications should be a fundamental part of the decision-making process when choosing the right gas line crimping tool for your project.

Maintenance Tips to Ensure Longevity and Optimal Performance of Your Crimping Tool

When it comes to choosing the best gas line crimping tool for your projects, maintenance is key to ensuring longevity and optimal performance. Regularly inspect the crimping dies for wear and tear, as worn tools can compromise the integrity of gas connections. Cleaning the tool after each use prevents debris buildup that could affect performance. Furthermore, lubricating moving parts periodically helps maintain smooth operation, extending the life of your tool.

As you decide on the materials for your piping projects, consider the interplay between tool maintenance and material performance. If you are replacing old piping, understanding the differences between options like PEX and copper can influence your choice of tool as well. For instance, PEX often requires different crimping techniques compared to copper. By aligning your tool maintenance practices with your piping material choices, you can ensure that every connection you make is reliable and durable, ultimately leading to successful project outcomes.

Related Posts

-

The Future of Home Heating How Gas PEX Systems Are Transforming Energy Efficiency

-

Why Choosing the Right Gas Ball Valve is Essential for Industrial Safety and Efficiency

-

Maximizing Efficiency: The Essential Guide to Choosing the Right Gas Ball Valve for Your Needs

-

Mastering the Art of Propane Gas Torch Kits: Essential Tips and Techniques for DIY Enthusiasts