The Ultimate Guide to 8mm Gas Pipe Fittings for 2025 Top Uses and Applications

In the evolving landscape of gas distribution and plumbing, the significance of 8mm gas pipe fittings remains paramount for both residential and industrial applications. According to a report by the Global Pipe Fittings Market Analysis, the demand for specialized fittings, particularly in the gas sector, is projected to grow at a steady rate of approximately 5.6% annually through 2025. This surge is largely driven by advancements in safe gas handling and an increase in infrastructure development around the world.

Expert in gas supply and distribution, Dr. William Marquez, states, "The adaptability and reliability of 8mm gas pipe fittings are crucial in ensuring that systems are not only efficient but also adhere to the highest safety standards." His insights emphasize the role of these fittings in facilitating efficient gas connections for appliances ranging from water heaters to industrial boilers, thereby playing a vital part in maximizing energy efficiency and safety in various applications.

As we explore the ultimate guide to 8mm gas pipe fittings, we will delve into their top uses and applications, highlighting innovations in installation techniques, materials used, and industry best practices. Understanding these factors will empower professionals and consumers alike to make informed decisions in their projects, ensuring both quality and safety are upheld in gas management systems.

The Basics of 8mm Gas Pipe Fittings: An Overview

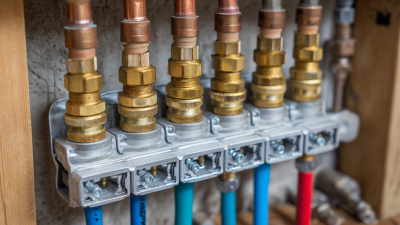

8mm gas pipe fittings are crucial components in various applications, primarily serving to connect and disconnect pipes in gas systems. Understanding the basics of these fittings is essential for anyone working with gas installations. These fittings are typically made of durable materials like brass or stainless steel, which provide resistance to corrosion and ensure safety in high-pressure environments. The standardization of 8mm dimensions makes these fittings versatile and compatible with various gas appliances and infrastructure.

In gas installation projects, 8mm fittings play a prominent role in facilitating efficient gas flow. Their compact size is ideal for connecting smaller piping systems commonly found in residential and commercial settings. The various types of fittings, such as elbows, tees, and couplings, enable seamless turns and branch connections in a gas line. Moreover, their ease of installation and removal allows for efficient maintenance, making them a preferred choice for both professionals and DIY enthusiasts. Understanding the characteristics and applications of 8mm gas pipe fittings is vital for ensuring safe and effective gas system operations.

Key Specifications and Standards for 8mm Gas Pipe Fittings

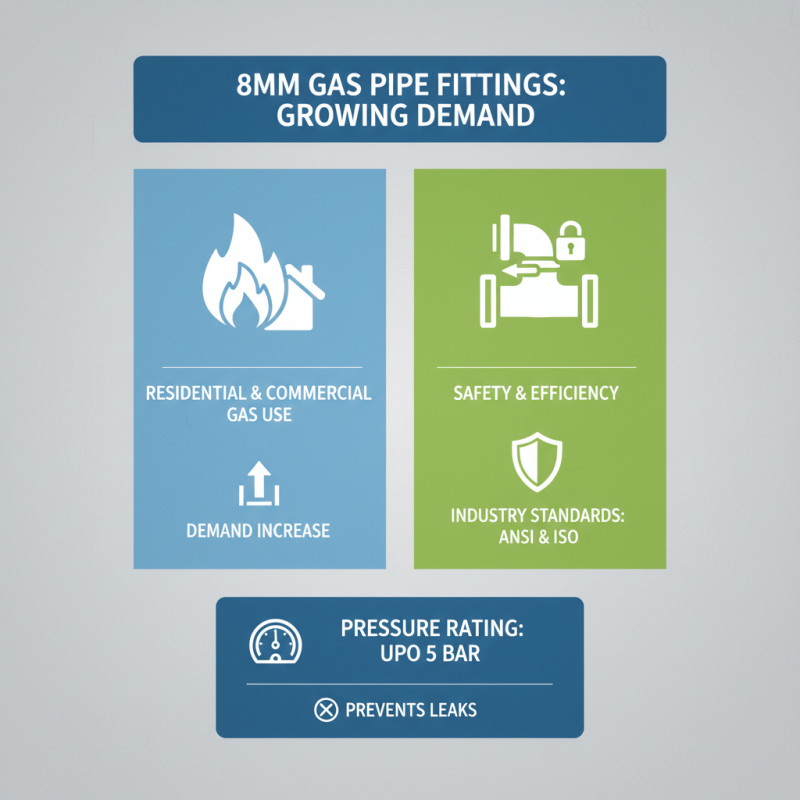

In recent years, the demand for 8mm gas pipe fittings has significantly increased, reflecting the growing use of natural gas in both residential and commercial applications. Key specifications for these fittings are crucial for ensuring safety and efficiency in gas distribution. According to industry standards outlined by organizations like the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO), 8mm fittings must meet specific pressure ratings and material compatibility to prevent leaks and ensure reliable performance. Typically, these fittings exhibit pressure ratings of up to 5 bar, making them suitable for various gas applications.

Materials used for 8mm gas pipe fittings include brass, stainless steel, and various polymers, each offering distinct advantages in terms of corrosion resistance and strength. For instance, brass fittings, which are widely regarded for their durability, comply with ASTM B16 specifications, ensuring they can withstand harsh environmental conditions while maintaining integrity over time. Meanwhile, polymer fittings have gained popularity due to their lightweight nature and resistance to chemical corrosion. As highlighted in a recent market analysis by Grand View Research, the proliferation of environmentally-friendly alternatives like polyethylene is reshaping industry standards, pushing manufacturers to innovate and adapt to evolving regulations. These considerations make it imperative for engineers and designers to stay informed about the latest specifications to optimize the applications of 8mm gas pipe fittings.

Top 5 Applications of 8mm Gas Pipe Fittings in Modern Industry

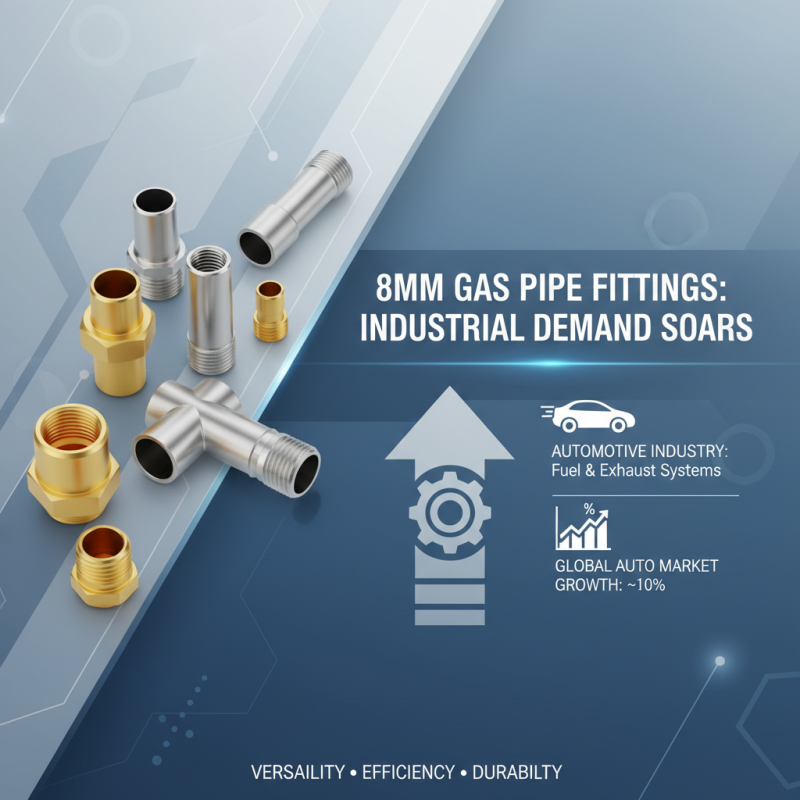

8mm gas pipe fittings are gaining prominence in various modern industrial applications, primarily due to their versatility and efficiency. One of the most significant uses of 8mm gas pipe fittings is in the automotive industry, where they are utilized in fuel systems and exhaust applications. According to a report from Statista, the global automotive market is projected to grow by approximately 10% in the coming years, fueling the demand for durable and reliable gas fittings that can withstand high pressures and temperatures.

Another vital application is in the residential and commercial heating sector. As energy efficiency becomes increasingly critical, 8mm gas pipe fittings are favored for their ability to deliver gas efficiently, minimizing energy loss. The Energy Information Administration reports that natural gas consumption for heating is expected to rise, underscoring the need for fittings that can support this trend. With rising standards for safety and efficiency, these fittings are essential in ensuring systems operate smoothly and effectively.

Additionally, 8mm gas pipe fittings are pivotal in the manufacturing sector, particularly in machinery that requires precise gas flow for operational efficiency. A report by IBISWorld highlights that the manufacturing industry is set to expand, with an emphasis on automation and efficiency. This growth necessitates the incorporation of reliable gas fittings, as they are critical in maintaining optimal performance and controlling gas flow in various applications.

Installation Tips and Best Practices for 8mm Gas Pipe Fittings

When it comes to installing 8mm gas pipe fittings, proper techniques and attention to detail are crucial for ensuring safety and efficiency. First, it's essential to select the right materials that comply with local regulations. For 8mm pipe systems, using high-quality fittings that match the pipe diameter will help create secure connections. Before installation, ensure all surfaces are clean and free of debris to promote a tight seal. Using thread sealants designed for gas applications can further prevent leaks and enhance durability.

During installation, it’s important to follow a systematic approach. Begin by measuring and cutting the gas pipes accurately, as improper lengths can lead to complications later. When joining fittings, avoid over-tightening, as this can damage the threads and compromise the integrity of the connection. Instead, use a torque wrench to apply the recommended pressure for optimal sealing. Regularly inspecting the connection points after installation is also advisable to catch any potential issues early, ensuring a long-lasting and safe gas system. Additionally, always follow the specific guidelines laid out by manufacturers and local codes, as these standards can vary depending on the application.

The Ultimate Guide to 8mm Gas Pipe Fittings for 2025 Top Uses and Applications

| Application | Type of Fitting | Material | Installation Tip |

|---|---|---|---|

| Residential Heating | Elbow Fitting | Brass | Ensure tight seals to prevent leaks. |

| Commercial Kitchens | Tee Fitting | Stainless Steel | Use thread sealant on all connections. |

| Gas Appliances | Straight Coupling | Copper | Check compatibility with appliance specifications. |

| Heating Systems | Reducer Fitting | PVC | Verify size before installation to ensure fit. |

| Outdoor Grills | Gas Valve | Aluminum | Install in a well-ventilated area. |

Future Trends: Innovations in 8mm Gas Pipe Fittings for 2025 and Beyond

As we move into 2025, the landscape of gas pipe fittings, particularly the 8mm variety, is set to undergo significant transformations driven by technological innovations and evolving industry standards. Research from the

Global Gas Equipment Market Report 2023 highlights that advancements in materials and designs are enhancing safety and efficiency. For instance, the introduction of corrosion-resistant and lightweight materials is expected to reduce installation and maintenance costs by approximately 20%, making 8mm gas pipe fittings more accessible for both residential and commercial applications.

Moreover, the integration of smart technologies within gas distribution systems is anticipated to become a game-changer. The Smart Gas Pipe Fittings Market Analysis by the Institute of Gas Technology projects a compound annual growth rate (CAGR) of 15% from 2023 to 2028. This trend reflects an increasing demand for fittings that not only facilitate gas flow but also incorporate sensors for real-time monitoring and leak detection, subsequently enhancing safety measures and operational efficiency. As the industry gravitates towards smart solutions, stakeholders are encouraged to focus on innovative designs that align with these future trends, ensuring that 8mm gas pipe fittings meet the rigorous standards expected in a rapidly evolving market.

Related Posts

-

The Future of Home Heating How Gas PEX Systems Are Transforming Energy Efficiency

-

Why Choose 8mm Gas Fittings for Your Home and Safety Needs

-

2025 How to Use LP Torch for Effective Welding and Metalwork Techniques

-

Maximizing Efficiency: The Essential Guide to Choosing the Right Gas Ball Valve for Your Needs

-

Top 2025 LPG Blow Torch Uses Tips and Buying Guide

-

Why Choosing the Right Gas Ball Valve is Essential for Industrial Safety and Efficiency