Top Gas Fittings Types and Their Applications?

Gas fittings play a vital role in various industries. They connect pipes and components, ensuring safe gas flow. Proper selection and installation of gas fittings enhance efficiency.

Different types of gas fittings exist, each designed for specific applications. For instance, connectors and adapters serve various pipeline configurations. Understanding which gas fittings to use can prevent leaks and hazards.

Yet, many users overlook the importance of quality in gas fittings. Cheap alternatives may save money but can lead to serious safety issues. It is crucial to consider both the type and quality of gas fittings being used.

Types of Gas Fittings and Their Essential Functions

Gas fittings are essential components in various applications. They connect pipes and equipment securely. These fittings ensure safe gas flow in residential and commercial settings. Understanding the types of gas fittings is crucial for efficiency and safety.

There are several common types of gas fittings. Compression fittings are popular for their reliability. They create a tight seal without needing special tools. Flared fittings, on the other hand, require precise cutting and flaring of pipes. This ensures a strong connection but demands skill. Another option is threaded fittings, which are cost-effective and easy to install. However, improper installation can lead to leaks.

Not all gas fittings are suitable for every application. It's vital to choose the right type for your needs. Some may rust over time, affecting performance. Regular inspection of your fittings can prevent issues. The wrong choice can cause inefficiencies or worse. Understanding each fitting type helps in making better decisions.

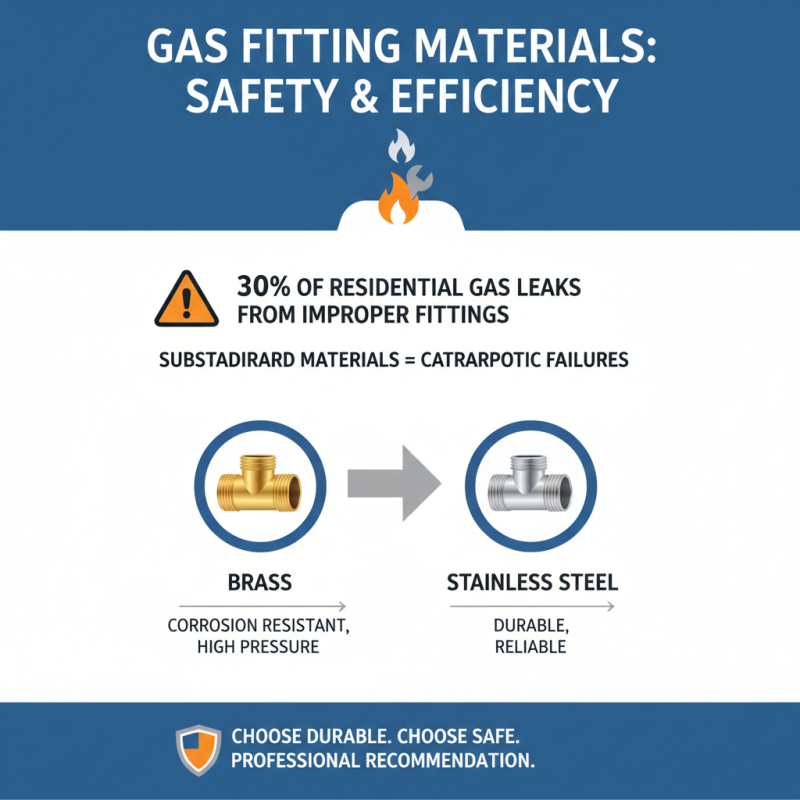

Understanding the Importance of Proper Gas Fitting Materials

Choosing the right gas fitting materials is crucial for safety and efficiency. Industry reports show that improper fittings account for 30% of gas leaks in residential areas. In many cases, substandard materials lead to catastrophic failures. The importance of using durable fittings cannot be overstated. Many professionals recommend brass and stainless steel for their resistance to corrosion and high pressure.

However, these materials can be expensive. Cost-saving options sometimes lead to the utilization of inferior fittings. This is a risky choice. Low-quality plastic fittings might break or corrode quickly. According to a 2022 safety report, replacing worn-out fittings annually can prevent up to 50% of incidents. This statistic highlights the importance of regular inspections.

Moreover, the environmental impact of gas leaks is significant. Reports indicate that methane leaks from faulty fittings contribute 25% to global warming. This underlines an urgent need for proper gas fitting practices. Investing in high-quality fittings may seem costly at first, but it could save money in the long term. Choosing the right material also supports a healthier environment. Making informed decisions is vital for both safety and sustainability.

Common Applications of Gas Fittings in Residential Systems

Gas fittings play a crucial role in the efficiency of residential systems. In homes, the most common gas fittings include connectors, elbows, and tees. Each serves a specific purpose. For instance, connectors link appliances to gas supply lines, ensuring safe operation. Elbows facilitate directional changes in piping systems. This connectivity creates a seamless flow of gas.

According to the American Gas Association, about 55% of residential heating uses natural gas. This statistic underscores the importance of effective gas fittings. Proper installation influences energy efficiency, impacting household bills. A report from the National Fuel Gas Code indicates that nearly 80% of gas-related incidents are due to improper fittings and connections. Such data points highlight the significance of quality fittings and skilled installation.

Moreover, gas leaks can pose serious hazards. Every year, thousands report gas leaks in homes. The consequences can be devastating. Regular maintenance is necessary. Homeowners should periodically inspect gas fittings for wear and tear. Ignoring this can lead to dangerous situations. Investing in proper fittings not only ensures safety but enhances overall system performance.

Top Gas Fittings Types and Their Applications

| Fitting Type | Description | Common Applications | Material |

|---|---|---|---|

| Coupling | Connects two pipes together | Connecting gas lines in residential and commercial settings | Copper, PVC |

| Elbow | Changes the direction of piping | Bending pipes around corners in gas systems | Steel, Brass |

| Tee | Allows for branch connections | Dividing gas flow into multiple directions | Copper, PEX |

| Valve | Controls the flow of gas | Shutting off gas supply at appliances | Brass, Steel |

| Regulator | Maintains consistent gas pressure | Gas appliances in homes | Aluminum, Brass |

Industrial Uses of Gas Fittings in Commercial Settings

Gas fittings play a crucial role in various industrial applications. They are essential in connecting pipes to appliances and ensuring the safe flow of gases. In commercial settings, gas fittings are found in kitchens, heating systems, and laboratories. A report by the Gas Appliance Manufacturers Association highlights that improper gas fittings lead to a significant number of safety hazards annually.

In kitchens, for example, gas fittings connect stovetops and ovens. Any failure in these fittings can result in gas leaks. According to the National Fire Protection Association, nearly 50% of kitchen fires are caused by cooking equipment, where faulty gas connections are often a contributor. The need for regular inspections and maintenance is clear but often overlooked.

Laboratories use gas fittings to supply various gases for experiments. Precision in these fittings is vital. A report by the American National Standards Institute shows that even small leaks can skew experimental results. Many industrial settings underestimate the importance of regular checks on these fittings. This oversight can lead to costly errors and potential safety risks, underscoring the need for ongoing education about gas fitting usage and maintenance in all sectors.

Safety Regulations and Standards for Gas Fitting Installation

Gas fitting installations require strict adherence to safety regulations. According to the National Fire Protection Association (NFPA), improper fittings can lead to hazardous leaks. Each year, these leaks contribute to thousands of fire incidents. Proper installations can significantly reduce these risks.

Regulatory bodies, such as the American National Standards Institute (ANSI), set specific standards for installation practices. Fittings must withstand certain pressure levels and corrosive environments. Failing to adhere to these standards can result in dangerous failures. A 2022 report noted that 30% of gas-related accidents were tied to incorrect fittings installation.

Regular inspections are vital. Many jurisdictions mandate annual checks to ensure compliance. Yet, compliance rates vary widely. A survey revealed that only 60% of households participate in regular inspections. This highlights a critical gap in safety awareness. Relying solely on regulations may not be enough. Encouraging proactive safety measures among homeowners remains a significant challenge.

Related Posts

-

2025 Top Trends in Gas Fittings for Home and Commercial Use

-

2025 How to Choose the Right Gas Ball Valve for Your Needs

-

Exploring the Efficiency: How 8mm Gas Pipes Improve Natural Gas Distribution Systems

-

What is an LPG Hose Connector and How to Choose the Right One

-

Understanding the Importance of Propane Shut Off Valves: Safety Tips and Best Practices

-

Ultimate Guide with 10 Essential Tips for Using a Propane Blow Torch