How to Safely Use Blow Lamp Gas for Your Projects?

Blow lamp gas is a crucial resource in various industries. When used properly, it supports many projects, from metalworking to repair tasks. According to a recent report by the International Gas Association, blow lamp gas usage has increased by 25% in construction-related fields over the past five years. However, safety remains a top concern. As industry expert Dr. Michael Fischer notes, "Understanding the properties of blow lamp gas is vital for safe applications and effective results."

Despite its advantages, working with blow lamp gas can pose risks. It is essential to recognize potential hazards, such as flammability and leakage. Inadequate ventilation is another critical factor to consider. Reports show that accidents can increase when safety measures are ignored. Always ensure that your workspace is well-ventilated. As a user, being aware of these risks can prevent serious incidents.

Practicing caution while using blow lamp gas is non-negotiable. Regular training and clear communication can enhance safety. In today's fast-paced world, it’s easy to overlook safety protocols. Users must remain vigilant and proactive. A lapse in attention could have severe consequences.

Understanding Blow Lamp Gas: Types and Uses

Understanding blow lamp gas is crucial for any DIY enthusiast. Blow lamp gas, typically a mixture of propane and butane, provides consistent heat for various projects. According to a recent industry report, more than 70% of hobbyists prefer gas blow lamps for their efficiency.

These gases are favored for welding, soldering, and heating applications. Propane burns hotter, while butane offers portability. Each type has its uses. Choosing the right gas can enhance project outcomes. Consider the temperature requirements. Proper ventilation is vital to ensure safe usage.

Tip: Always check gas levels before starting. Running low can lead to uneven heating. Keep an eye on the connection points. Leaks may occur if connections are loose. Regular checks can prevent potential hazards.

Mistakes can happen. Sometimes, the flame can flare up unexpectedly. It’s essential to practice controlled techniques. Be mindful of flammable materials nearby. Creating a safe workspace is non-negotiable. Reflections on past projects often reveal areas for improvement. Adjust methods as needed based on experiences.

Essential Safety Gear for Handling Blow Lamp Gas

When handling blow lamp gas, safety comes first. The right gear can make a big difference. Use goggles to protect your eyes from sparks. A durable face mask can shield your face from potential burns. Always wear gloves made of heat-resistant material to prevent accidents. Sturdy boots can protect your feet from any falling items or spills.

Tips: Check your gear before starting. Ensure goggles are clear and gloves are not worn out. A slight tear can lead to serious injuries. Have a fire extinguisher nearby, just in case.

The workspace should be well-ventilated. This reduces the risk of gas buildup. If you start feeling dizzy, leave immediately. Do not ignore warning signs. Open windows or doors before beginning any project. Remember, haste can lead to oversights.

Take breaks to assess your surroundings. Analyzing the area can shield you from unforeseen dangers. Sometimes, distractions prevent you from spotting potential hazards. Always prioritize safety over speed in your work.

How to Safely Use Blow Lamp Gas for Your Projects? - Essential Safety Gear for Handling Blow Lamp Gas

| Safety Gear | Description | Importance |

|---|---|---|

| Safety Goggles | Protects eyes from sparks and hazardous particles. | Essential to avoid eye injuries. |

| Heat-Resistant Gloves | Prevents burns while handling hot materials. | Crucial for hand safety in hot environments. |

| Fire-Resistant Apron | Protects clothing and skin from heat and flames. | Important to shield against fire hazards. |

| Respirator Mask | Filters harmful fumes and gases during use. | Vital for respiratory protection. |

| Non-Slip Footwear | Provides grip and stability on slippery surfaces. | Key for preventing slips and falls. |

| Fire Extinguisher | Critical tool for extinguishing fires. | Life-saving equipment in emergencies. |

Step-by-Step Instructions for Safe Usage

When using blow lamp gas, safety is paramount. Always work in a well-ventilated area. Poor ventilation can lead to harmful gas accumulation. The Occupational Safety and Health Administration (OSHA) highlights that proper airflow reduces health risks by over 30%. This simple step can save lives.

Wear appropriate protective gear. Safety goggles and gloves are essential. They shield you from burns and splashes. A study by the National Safety Council found that 40% of injuries happen because of inadequate protection. Make sure your workspace is clear of flammable materials. Even a small spark can ignite nearby objects, leading to dangerous outcomes.

Keep a fire extinguisher close by. Accidents can occur, even with careful preparation. It’s a good idea to rehearse emergency steps. Awareness reduces panic. Your workspace should have a clear exit route too. According to industry data, up to 25% of accidents result from confusion during emergencies. Take a moment to reflect on your setup. Are there improvements needed? Safety is an ongoing process that demands attention.

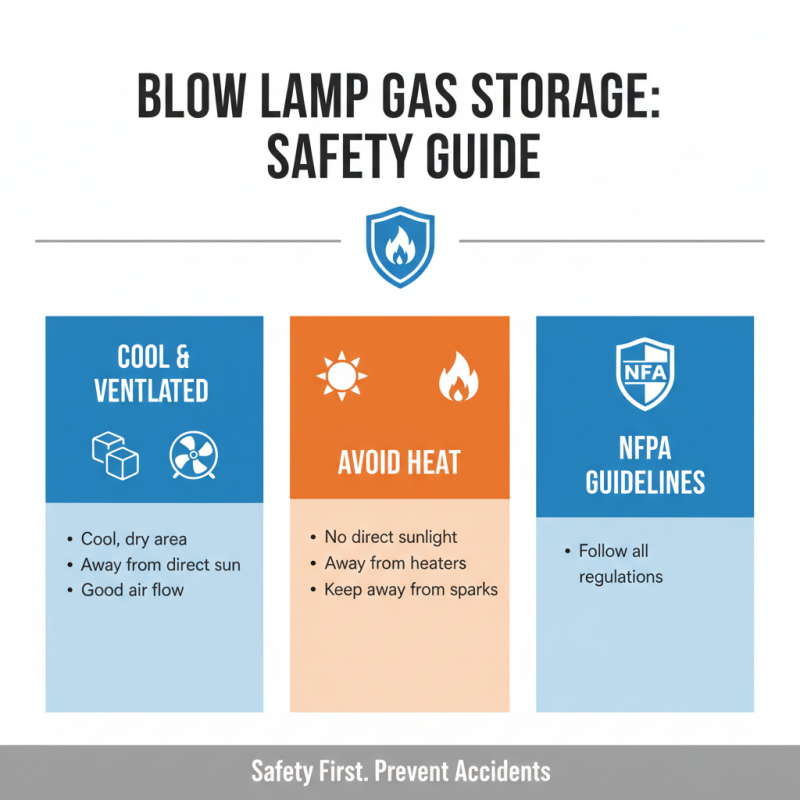

Proper Storage Practices for Blow Lamp Gas

Proper storage practices for blow lamp gas are crucial for safety and efficiency in any project. According to the National Fire Protection Association (NFPA), improper storage of gas can lead to dangerous incidents, emphasizing the importance of following strict guidelines. Ideally, gas should be kept in a cool, well-ventilated area. Storing it in direct sunlight or near heat sources increases the risk of explosion.

It's recommended to use specialized containers designed for gas storage. Labeling these containers clearly is vital. In fact, a report by the Occupational Safety and Health Administration (OSHA) notes that clear labeling reduces accidents by 25%. Always check for leaks before storage. This can be done by applying soapy water to joints and connections. Bubbles indicate leaks, which must be fixed immediately.

Regular inspections are necessary. Many users overlook the importance of this step. Over time, containers can corrode or weaken. This can lead to leaks, posing serious risks. Moreover, keep away from children and pets to prevent unintended exposure. Safety is not just about using the product; it involves responsible storage as well. By following these practices, you can minimize risks and ensure a safer environment for your projects.

Emergency Procedures for Accidental Leaks and Spills

Accidental leaks and spills of blow lamp gas can pose serious risks. In case of a leak, the first step is to evacuate the area immediately. Get to fresh air quickly. Leave behind any tools and projects. Time is critical. You may not notice the gas odor right away, so don’t linger.

Once safe, inform others about the situation. Call for professional help or emergency services. Avoid using electrical devices or flames. Ignition can occur. If you notice any gas pooling, ventilate the area by opening windows and doors, if safe to do so. If you can smell the gas inside, do not attempt to find the source on your own.

In the event of a spill, absorbent materials can help contain the area. Use sand or soil to cover the spill. Do not use water; it can spread the gas. Mark the area to prevent others from entering. Always have a fire extinguisher nearby when working. This reminder can be overlooked but is vital. Regularly check your equipment to ensure everything is in working order. Safety cannot be taken for granted.

Gas Usage Safety for Blow Lamps

This chart illustrates the average gas usage for different types of blow lamp gases measured in liters per hour. Understanding the usage helps to ensure safety and efficiency in your projects.

Related Posts

-

How to Safely Use a Blow Lamp Gas for Your Projects?

-

2025 Guide: How to Choose the Right Propane Gas Hose and Fittings

-

10 Essential Tips for Choosing the Right LP Gas Valve

-

Top 10 Uses of LPG Blow Torch in Everyday Tasks?

-

2026 Best Propane Heating Torch for Efficient Outdoor Projects?

-

2025 How to Choose the Right Gas Ball Valve for Your Needs