Maximizing Efficiency: The Essential Guide to Choosing the Right Gas Ball Valve for Your Needs

In the quest for optimizing fluid control and operational efficiency within industrial applications, selecting the right instrumentation is crucial. One of the pivotal components often overlooked is the gas ball valve. According to a recent market research report by MarketsandMarkets, the global valve market is expected to reach USD 88.6 billion by 2027, with gas ball valves playing a significant role due to their reliability and durability in handling various gases. As industries strive to enhance productivity while minimizing downtime and maintenance costs, the demand for high-quality gas ball valves continues to surge. This essential guide will delve into the crucial factors to consider when selecting a gas ball valve, ensuring that you maximize efficiency and meet your specific operational needs. By understanding the intricacies of this vital equipment, businesses can ensure optimal performance and longevity in their gas handling systems.

Understanding Gas Ball Valve Types and Their Applications

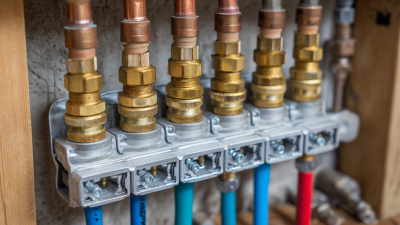

When selecting a gas ball valve, understanding the different types and their applications is crucial for maximizing efficiency. Gas ball valves generally come in two primary types: full-port and reduced-port. Full-port valves have a larger ball and provide minimal resistance to flow, making them ideal for applications where maximum flow is necessary. In contrast, reduced-port valves are more compact, which can save space in installations where flow rates are not as critical.

**Tip:** Always assess the specific requirements of your system—consider factors such as pressure, temperature, and the nature of the gas. This will help you determine whether a full-port or reduced-port valve is best suited for your needs.

Another essential factor to consider is the material of the gas ball valve. Common materials include brass, stainless steel, and plastic, each offering unique benefits depending on the application. Brass valves are often cost-effective for low-pressure systems, while stainless steel valves provide excellent durability in harsher environments.

**Tip:** If your system is exposed to corrosive gases or extreme temperatures, opt for materials designed to withstand such conditions to ensure longevity and performance.

| Valve Type | Material | Pressure Rating (PSI) | Temperature Range (°F) | Applications |

|---|---|---|---|---|

| Standard Ball Valve | Brass | 150 | -10 to 200 | Water, Oil, Gas |

| Forged Steel Ball Valve | Steel | 600 | -20 to 400 | High-Pressure Systems |

| PVC Ball Valve | PVC | 80 | 32 to 140 | Chemical, Water Treatment |

| Stainless Steel Ball Valve | Stainless Steel | 300 | -40 to 300 | Food Grade, Pharmaceuticals |

| Electric Ball Valve | Various | 150 | -20 to 150 | Automation Systems, HVAC |

Key Factors to Consider When Choosing a Gas Ball Valve

When selecting a gas ball valve, several key factors can significantly influence efficiency and performance.

First and foremost, the valve size should match the specific requirements of your system to ensure optimal flow rates and pressure conditions. A valve that is too small can restrict flow, leading to pressure drops and reduced system efficiency, whereas an oversized valve might lead to turbulence and inefficiencies in operation.

Another important consideration is the material composition of the valve. Depending on the application, valves made from various materials can withstand different temperatures and pressures, ensuring durability and reliability. Additionally, look into the valve's sealing capability, as a strong seal will prevent leaks and maintain system integrity over time.

Finally, it’s crucial to assess the valve’s compatibility with existing system components, including any auxiliary devices like regulators and sensors. By keeping these factors in mind, you will be better equipped to choose a gas ball valve that not only meets your specific needs but also maximizes overall system efficiency.

Evaluating Materials and Construction for Maximum Durability

When selecting a gas ball valve, the materials and construction play a critical role in ensuring maximum durability and efficiency. According to a recent report by the International Valve Standards Organization, nearly 30% of valve failures are attributed to material degradation caused by environmental factors. Therefore, opting for high-quality materials like stainless steel or brass can significantly enhance the lifespan of gas ball valves, particularly in corrosive environments. Stainless steel, for example, offers exceptional resistance to rust and wear, making it a preferred choice for many industries.

In addition to the material, the construction techniques employed in manufacturing these valves are equally important. Valves that are forged tend to exhibit greater strength and reliability compared to those that are cast. A study by the American Society of Mechanical Engineers found that forged valves can withstand pressures up to 40% higher than their cast counterparts. This makes them ideal for high-pressure gas applications where safety is paramount. Given these considerations, investing in durable materials and advanced construction techniques is essential for maximizing both the operational efficiency and longevity of gas ball valves.

Installation Tips for Ensuring Optimal Valve Performance

When it comes to installing a gas ball valve, proper techniques and precautions are essential for ensuring optimal performance. Before you start, make sure the installation area is clean and free from any debris. This will help prevent any contaminants from entering the system. Additionally, check that the valve is the correct type for your specific application, as using the wrong valve can lead to inefficiencies and potential hazards.

One critical tip during installation is to avoid over-tightening the valve. While it’s important to ensure that the connections are secure, excessive force can damage the valve's seals and threads, leading to leaks. Use the manufacturer's recommended torque specifications as a guideline. It’s also advisable to use thread sealant on the valve threads to ensure a tight seal, but be cautious not to let sealant enter the valve body.

Lastly, after installation, conduct a thorough leak test. This can be done by applying a soapy water solution to the joints and observing for bubbles, which indicate leaks. Regular maintenance checks after installation will also help sustain the valve’s performance and extend its lifespan. By following these installation tips, you can ensure your gas ball valve operates efficiently and effectively for years to come.

Maintenance Practices to Enhance the Lifespan of Gas Ball Valves

Maintenance is key to ensuring the longevity and optimal performance of gas ball valves. Regular inspection and cleaning can prevent buildup that may impede functionality. One important tip is to create a routine maintenance schedule that includes checking for leaks, ensuring that the valve operates smoothly, and inspecting seals for wear and tear. Performing these checks periodically can help identify potential issues before they become serious problems.

Maintenance is key to ensuring the longevity and optimal performance of gas ball valves. Regular inspection and cleaning can prevent buildup that may impede functionality. One important tip is to create a routine maintenance schedule that includes checking for leaks, ensuring that the valve operates smoothly, and inspecting seals for wear and tear. Performing these checks periodically can help identify potential issues before they become serious problems.

In addition to regular inspections, lubrication is crucial for enhancing the lifespan of gas ball valves. When lubricating, use a high-quality grease recommended for gas applications to minimize wear on the moving parts. A helpful tip is to apply lubrication during maintenance checks, ensuring the valve operates without unnecessary friction or resistance. This practice not only extends the life of the valve but also improves efficiency in gas flow.

Lastly, environmental factors play a significant role in the health of your gas ball valves. Ensure the valves are installed in areas protected from extreme temperatures and corrosive elements. Consider using protective covers to shield the valves from harsh conditions. Implementing these maintenance practices will significantly enhance the lifespan and reliability of your gas ball valves.