Top Tips for Using LP Torch Effectively in Your Next Project

When embarking on a new project that involves welding or cutting, mastering the use of the LP torch can significantly enhance your efficiency and precision. The LP torch is a versatile tool that relies on liquefied petroleum gas to produce a focused flame suitable for various tasks. However, to harness its full potential, one must understand the nuances of operation and safety. Implementing best practices not only ensures effective outcomes but also promotes a safer working environment.

In this guide, we will explore essential tips and techniques that will empower you to utilize the LP torch with confidence and skill. From proper setup and maintenance to understanding flame adjustment and safety protocols, each aspect plays a crucial role in achieving optimal results. Whether you are a seasoned professional or a novice, these insights will pave the way for a successful project while maximizing the benefits of your LP torch. Join us as we delve into the details that can make your next endeavor not just productive but also remarkably successful.

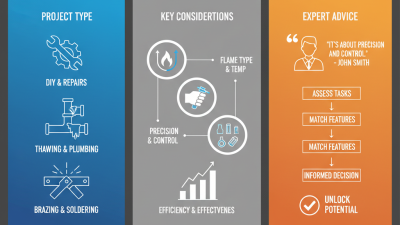

Understanding the Basics of LP Torch: Features and Capabilities

LP Torch is a powerful tool designed for precision lighting in various projects. Its features include adjustable flame control, lightweight design, and ergonomic handling, making it suitable for both professionals and DIY enthusiasts. The adjustable flame allows users to tailor the intensity based on the requirements of the task, whether it’s for soldering, crafting, or culinary uses. Understanding these foundational features can significantly enhance your effectiveness when using the LP Torch in your projects.

To maximize the potential of the LP Torch, it's essential to employ some best practices. First, ensure you have a proper workspace that’s well-ventilated and free of flammable materials. This will not only ensure your safety but also optimize your ability to focus on the task at hand. Secondly, practice using the torch on scrap materials before starting on your main project. This helps you get a feel for the flame control and prevents any mishaps that could occur due to inexperience.

Another tip is to maintain the torch properly, including regular cleaning and checking for any gas leaks. A well-maintained tool functions better and offers more consistent results. Additionally, don’t forget to familiarize yourself with the safety features of the LP Torch, as knowing how to handle it responsibly will lead to a more efficient and enjoyable experience.

Top Tips for Using LP Torch Effectively in Your Next Project - Understanding the Basics of LP Torch: Features and Capabilities

| Feature | Description | Use Case | Tip |

|---|---|---|---|

| Variable Power Settings | Allows users to adjust the intensity of the flame for different tasks. | Used for precision heating or rapid melting. | Start at a lower power setting and gradually increase to avoid overheating. |

| Ergonomic Design | Designed for comfortable handling during extended use. | Ideal for DIY projects and professional applications alike. | Ensure a proper grip to reduce fatigue and maintain control. |

| Safety Features | Includes features like flame control systems and safety locks. | Essential for ensuring safe operation in various environments. | Always engage safety locks when not in use. |

| Versatile Attachments | Compatible with different nozzles for specialized applications. | Useful for tasks ranging from soldering to culinary applications. | Select the appropriate nozzle based on your project requirements. |

| Lightweight Construction | Designed to be portable without sacrificing durability. | Great for on-site work or projects requiring mobility. | Keep your workspace organized to easily transport your torch and accessories. |

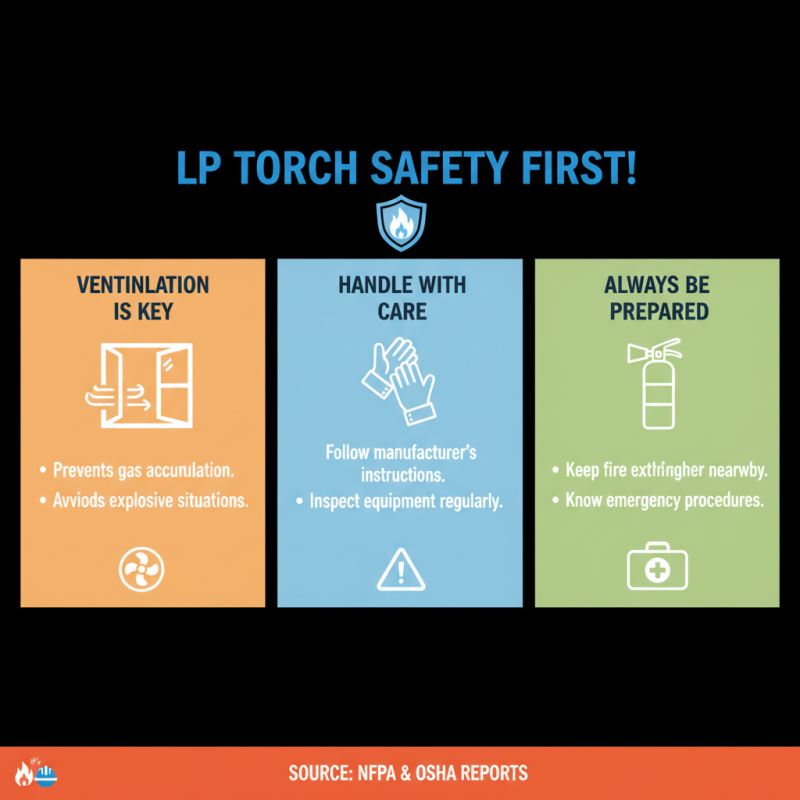

Essential Safety Measures When Using LP Torch in Projects

When using an LP torch in project work, ensuring safety should be a top priority. According to the National Fire Protection Association (NFPA), improper handling of flammable gases can lead to severe accidents, causing injuries and property damage. Ensuring proper ventilation is essential, as gases can accumulate in enclosed spaces, leading to explosive situations. A report by the Occupational Safety and Health Administration (OSHA) indicates that more than 4,000 workplace injuries related to torch use are reported annually, underscoring the need for comprehensive safety measures.

It is crucial to equip oneself with the right personal protective equipment (PPE) when using an LP torch. The NFPA recommends wearing flame-resistant clothing, safety goggles, and heat-resistant gloves to protect against burns and eye injuries. Furthermore, ensuring that the area is clear of any flammable materials is vital, as per guidelines from the National Institute for Occupational Safety and Health (NIOSH). Keeping a fire extinguisher readily accessible can help mitigate risks should an incident occur. Safe handling practices, combined with appropriate training on emergency procedures, form the backbone of a safe working environment when using LP torches in various projects.

Techniques for Maximizing Efficiency with LP Torch

When approaching projects that utilize LP Torch, maximizing efficiency is crucial for achieving optimal results. Techniques such as pre-heating materials before application can significantly enhance the torch's performance. According to a recent industry report by the Welding Institute, pre-heating can increase the overall efficiency of torch operations by as much as 20%. This process reduces the time spent on heating during application, ensuring a faster workflow while maintaining quality.

Another effective technique involves optimizing the torch’s flame settings tailored to specific materials. Research indicates that adjusting gas mixtures and pressure settings can yield improvements in flame stability and control, which is vital for precision tasks. A comprehensive study from the American Welding Society discovered that users who fine-tuned their LP Torch settings could improve their productivity levels by 15% compared to those using default settings. By understanding the thermodynamic properties of the materials involved and adapting the torch accordingly, professionals can create stronger bonds and minimize waste.

Additionally, keeping the work area organized and using proper safety equipment not only enhances efficiency but also ensures a safer working environment. A report from the Occupational Safety and Health Administration states that up to 30% of workplace injuries can be mitigated through effective workspace management. Implementing these best practices will not only elevate project outcomes but also streamline operational processes when using LP Torch.

Common Mistakes to Avoid While Working with LP Torch

When leveraging LP Torch for your next project, being aware of common pitfalls can help maximize efficiency and output quality. One major mistake is neglecting to adjust the flame intensity according to the material being used. According to industry insights from the American Welding Society, improper flame settings can lead to material degradation, resulting in weakened structural integrity. For example, using too high of a flame on thinner metals often results in warping or melting, whereas insufficient heat can fail to adequately bond materials.

Another frequent error is overlooking safety protocols. The Occupational Safety and Health Administration (OSHA) emphasizes that inadequate safety measures can lead to severe accidents. Proper ventilation, the use of personal protective equipment, and adhering to recommended distancing can mitigate risks associated with working with LP Torch. Statistics indicate that approximately 3,400 injuries occur annually in welding-related activities due to such oversights. By prioritizing safety and adjusting technical settings based on materials, users can significantly enhance project outcomes while minimizing risks.

Top Tips for Using LP Torch Effectively in Your Next Project

This chart illustrates the common mistakes to avoid while working with LP Torch, focusing on aspects like preparation, technique, and safety measures.

Maintenance and Care Tips for Longevity of Your LP Torch

To ensure the longevity of your LP torch, regular maintenance is essential. Begin by cleaning the torch after each use. Allow the torch to cool down completely, then wipe down the exterior with a damp cloth to remove any residue. For more thorough cleaning, take apart the components where possible and clean them separately according to the manufacturer’s instructions. Pay particular attention to the nozzle and fuel lines, as blocked pathways can affect performance and safety.

Additionally, inspect your LP torch periodically for any signs of wear or damage. Check the hoses for cracks or leaks, and ensure all connections are tight. Use soapy water to test for leaks; any bubbles forming indicates a leak that needs addressing. Keeping the torch stored in a dry, cool place when not in use helps prevent rust and degradation, further contributing to its lifespan. By following these maintenance and care tips, you can enjoy your LP torch safely and effectively for many projects to come.

Related Posts

-

2025 How to Use LP Torch for Effective Welding and Metalwork Techniques

-

2025 Guide: How to Choose the Best LP Torch for Your Crafting Needs

-

How to Choose the Best Propane Heating Torch for Your Projects Guide

-

Top 10 Essential Gas Fitting Supplies for Every DIY Enthusiast

-

Maximizing Efficiency: The Essential Guide to Choosing the Right Gas Ball Valve for Your Needs

-

Why Choosing the Right Gas Ball Valve is Essential for Industrial Safety and Efficiency