How to Choose the Right Propane Torch Nozzle for Your Projects?

Choosing the right propane torch nozzle for your projects is essential. It can significantly affect your work's efficiency and quality. A suitable nozzle provides optimal flame control and precision, helping you achieve the desired results.

When selecting a propane torch nozzle, consider the specific task you need it for. Different nozzles offer varying flame sizes, which can influence the heating process. For instance, larger nozzles may cover more area but might lack the fine control needed for detailed work.

It’s also important to reflect on your comfort level with the tool. Familiarity with different nozzles can affect your decision. Remember, a nozzle that works well for one project might not suit another. Be careful not to rush your choice; it’s worth taking the time to evaluate your options carefully.

Understanding Propane Torch Nozzles: Types and Uses

Propane torch nozzles come in various types, each suited for specific applications. For example, the wide-angle nozzle is ideal for large surface areas. It disperses heat evenly, making it perfect for tasks like thawing frozen pipes or soldering. Reports indicate that using the right nozzle can enhance efficiency by up to 30%. This efficiency not only saves time but also reduces the amount of propane consumed during projects.

On the other hand, the narrow nozzle focuses heat in a smaller area. This is beneficial for detailed work, such as brazing or metalworking. However, users must be cautious. A narrow focus can lead to overheating and damage surrounding materials. It's crucial to practice and gain experience with different nozzles. Misjudging the heat application can lead to unexpected results, which is not ideal for precision work.

Considering the right nozzle type is vital. Understanding their uses can significantly impact the outcome of your projects. Research shows that improper nozzle selection can result in failed tasks, leading to additional expenses. Reflecting on your experience and adjusting techniques can help improve results. The balance between efficiency and precision matters in every project you undertake.

Factors to Consider When Selecting a Propane Torch Nozzle

When selecting a propane torch nozzle, consider several crucial factors. The nozzle’s size directly affects the flame type and intensity. A larger nozzle can produce a wider flame, useful for big projects, while smaller nozzles are ideal for detailed work. According to industry data, a 0.5-inch nozzle typically produces a flame temperature reaching up to 3,600°F, making it a go-to for soldering.

Another aspect to reflect on is the material of the nozzle. Steel nozzles are durable but can corrode over time. Brass offers better resistance to heat, though it may not provide the same longevity when exposed to harsh conditions. Many professionals report that opting for a brass nozzle increases their tool's lifespan by over 30%.

Don’t forget to evaluate the nozzle tip design. Some users prefer adjustable tips for versatility. However, they can complicate maintenance. It's often noted that a simpler design is easier to clean but may lack the flexibility needed for varied applications. Choosing the right torch nozzle is complex and demands careful thought. Mistakes can lead to costly project setbacks or unsafe working conditions.

Matching Nozzle Size with Project Requirements

Choosing the right propane torch nozzle is crucial for various projects. The size of the nozzle directly affects the flame's intensity and spread. For fine soldering, a smaller nozzle is ideal; it provides precision. On the other hand, large nozzles produce a wider flame, suitable for tasks like metal brazing.

Understanding the project requirements is essential. If you need quick heating, a larger nozzle might seem better. However, it can lead to overheating sensitive areas. Conversely, a tiny nozzle could struggle with larger applications. An imbalance like this can damage materials. Testing different sizes on scrap pieces helps avoid mistakes.

Some nozzles may not fit your torch perfectly. Poor fit can lead to leaks or inefficient burning. Always double-check compatibility. While it’s easy to overlook, this step is vital for safety and effectiveness. Proper airflow and propane mixing are often overlooked details that impact performance significantly.

Propane Torch Nozzle Size vs. Project Applications

Safety Considerations for Using Propane Torch Nozzles

Using a propane torch nozzle comes with safety considerations that should not be overlooked. Poor handling can lead to burns or fires. In fact, the U.S. Consumer Product Safety Commission reported that about 16,000 injuries occur annually due to improper use of torches. Awareness of the risks is the first step in ensuring safety.

Before starting any project, inspect your equipment closely. Check for leaks and ensure that connections are secure. This simple step can prevent dangerous situations. Always work in a well-ventilated area. Propane is flammable and can accumulate, igniting unexpectedly. Having a fire extinguisher nearby is not just smart; it’s essential.

Tips: Wear protective gear like gloves and goggles. This protects against accidental burns or flying debris. Familiarize yourself with the nozzle you use. Understand its capabilities and limitations. Improper usage can lead to frustration and potential hazards. Take your time; rushing increases the chances of mistakes. Always respect the power of the flame. Remind yourself that safety comes first in any project.

Maintenance Tips for Prolonging Nozzle Lifespan

When using a propane torch, the nozzle is crucial. A well-maintained nozzle ensures precision and safety in your projects. Regular maintenance can significantly extend its lifespan. Clean the nozzle after use. Dirt and debris can accumulate and affect performance.

Here are some tips to keep your nozzle in top shape. Always store it in a dry place. Moisture can lead to rust, which damages the metal. Check for any leaks or damage frequently. Even small cracks can cause issues. If you notice anything unusual, replace the nozzle promptly.

Another important aspect is temperature control. Overheating can distort the nozzle shape. Avoid using it beyond recommended limits. If you find yourself using excessive heat, reevaluate your technique. Being mindful of how you handle the torch makes a difference.

Proper maintenance is not just for longevity; it also enhances your work's quality.

Related Posts

-

Top 2025 Propane Torch Kits for DIY Projects and Home Improvement

-

Ultimate Guide with 10 Essential Tips for Using a Propane Blow Torch

-

How to Choose the Best Propane Welding Torch for Your Projects

-

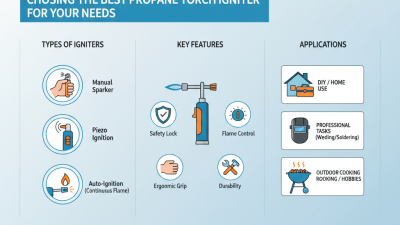

Choosing the Best Propane Torch Igniter for Your Needs

-

2025 Guide: How to Choose the Best LP Torch for Your Crafting Needs

-

2025 How to Choose the Right Gas Ball Valve for Your Needs