10 Best Gas Pipe Connectors for Safe and Efficient Gas Flow

In the realm of gas installations, safety and efficiency are paramount. A crucial component in ensuring these qualities is the gas pipe connector. Properly designed gas pipe connectors facilitate seamless gas flow while minimizing the risk of leaks. According to industry reports, improper connections account for a significant percentage of gas-related accidents. This underscores the importance of selecting reliable connectors for home and commercial use.

Gas pipe connectors come in various materials and designs. The choice of a connector can impact not only the flow rate but also the longevity of the system. A well-fitted gas pipe connector can withstand pressure fluctuations and environmental factors, ensuring consistent performance. However, it's essential to recognize that even the best products can fail if not installed correctly. Regular inspection and maintenance are key to preventing potential hazards.

As we delve into the ten best gas pipe connectors available today, remember that effective gas management is a shared responsibility. Choosing the right connector is just the first step. Awareness of installation techniques and regular checks should not be overlooked. Ultimately, everyone involved in gas handling must prioritize safety and reliability in every aspect of their work.

Types of Gas Pipe Connectors: An Overview of Options Available

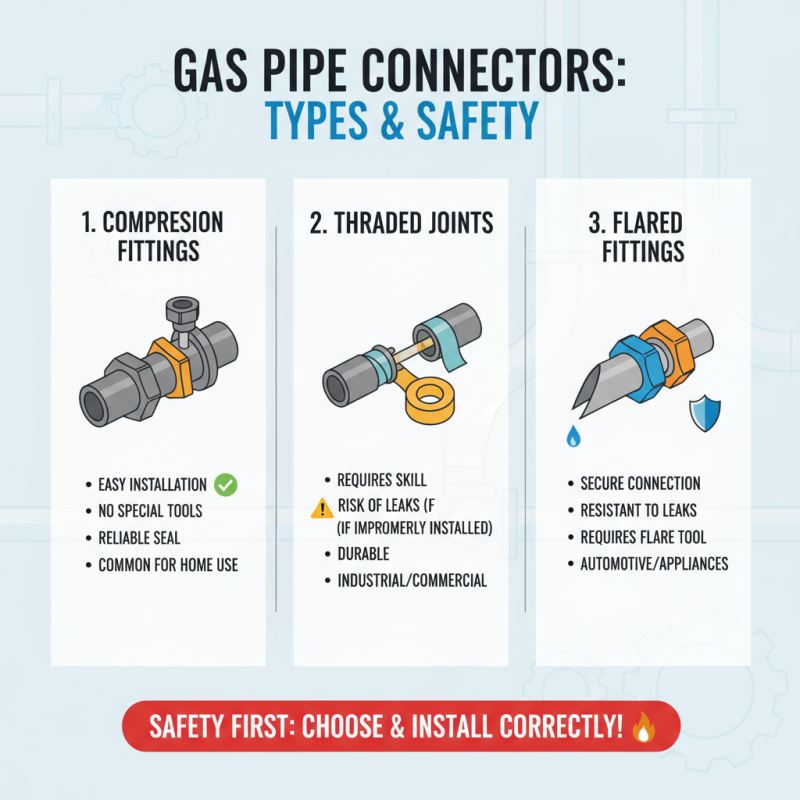

When it comes to gas pipe connectors, several options stand out based on safety, efficiency, and application. Common types include compression fittings, threaded joints, and flared fittings. Each type is designed for specific functionalities. Compression fittings are popular due to their ease of installation. They provide a reliable seal without extensive tools. Threaded joints often require more skill and might lead to leaks if not installed correctly. According to a recent industry report, improper installation can be a leading cause of gas leaks, emphasizing the importance of selecting the right connector.

Flared fittings, known for their durability, are often used in high-pressure applications. These connectors provide a strong seal but can be more complex to install. An estimated 15% of gas accidents occur due to faulty connections, reinforcing the need for proper installation. Some connectors are designed for specific gas types, like natural gas or propane. Understanding the differences helps prevent hazards. In some cases, cheaper options might save money upfront but can lead to higher risks. It's essential to weigh the cost against the long-term safety and efficiency.

While options are abundant, the right choice depends on specific needs and conditions. Factors like pressure rating and temperature resistance play crucial roles. Data indicates that nearly 30% of users may choose the wrong connector type, increasing risks of leaks. Awareness and education in connector selection are vital. The landscape of gas piping is complex, and making informed decisions is crucial for safety.

Key Features to Consider for Safe Gas Pipe Connectors

When choosing gas pipe connectors, safety is paramount. Look for durable materials like stainless steel or brass. These materials resist corrosion and ensure long-lasting use. Connectors should be designed to withstand high pressure. Weak connectors can lead to leaks.

Inspect the fittings regularly. Look for cracks or signs of wear. A small crack might seem insignificant, but it can become a bigger issue. Check for proper sealing. A well-sealed connector reduces the risk of gas escaping into the environment.

Tips: Always use connectors that fit your pipe size. An ill-fitting connector can compromise safety. Consider connectors with easy installation features. Complicated setups increase the chances of errors. Remember, the goal is efficiency and safety combined. A little attention to detail goes a long way in preventing accidents.

Top 10 Gas Pipe Connectors for Efficiency and Reliability

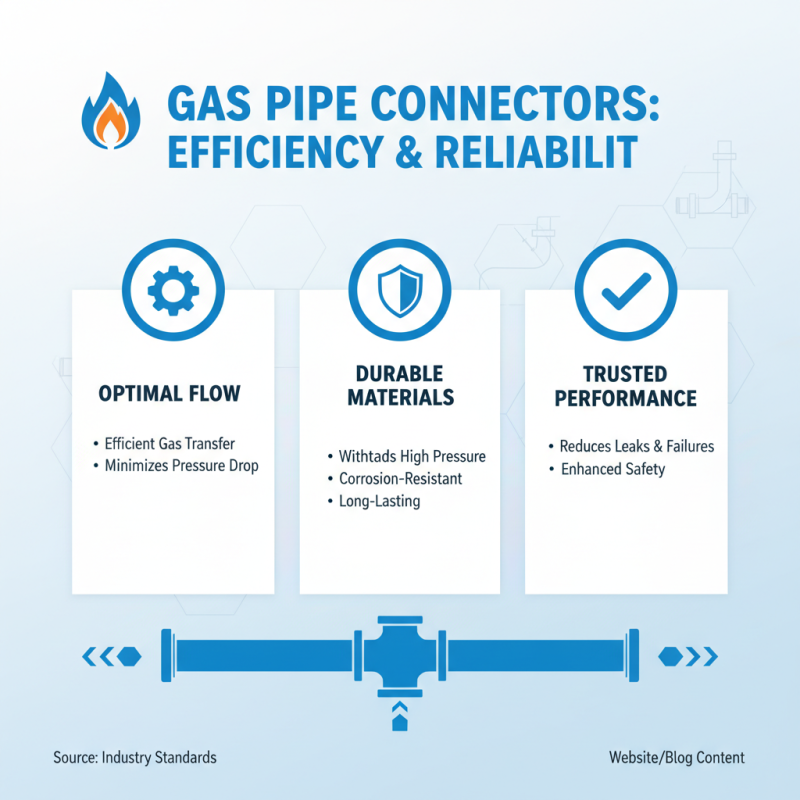

When choosing gas pipe connectors, efficiency and reliability are crucial. The materials used in connectors can significantly impact gas flow. Opt for connectors made from durable materials. They should withstand pressure and resist corrosion.

Tips: Always check the pressure rating of connectors. Not all are created equal. A mismatch can lead to leaks. Ensure proper installation techniques as well. Improper fittings can cause gas flow issues, leading to potential hazards.

Effective sealing is vital. Gaskets and threads should be in perfect condition. Worn or damaged components can compromise safety. Remember to always perform regular maintenance. Over time, wear can occur, impacting performance.

For optimized gas flow, always match connector sizes with the pipe diameter. Keep in mind that even slight discrepancies can lead to inefficiencies. Don’t overlook the importance of a reliable connection. A small oversight might cause significant problems later on.

Installation Tips for Gas Pipe Connectors to Ensure Safety

When installing gas pipe connectors, safety should be your top priority. A secure connection ensures efficient gas flow and prevents leaks. Always ensure the area is well-ventilated before starting your installation. This reduces the risk of inhaling harmful gases. Use proper tools and protective equipment during the process.

One critical tip is to check for compatibility between the connector and the gas pipe. Using mismatched parts can lead to dangerous leaks. After installation, apply a soap solution to check for any air leaks. Bubbles will form if there is a leak, indicating a need for immediate action.

Regular maintenance is key. Check connectors periodically for wear and tear. Replace any damaged parts immediately to prevent dangerous situations. Keep a close eye on gas flow. Irregularities could signal a potential issue with the connectors. Always trust your instincts; if something feels off, investigate further.

Maintenance and Safety Checks for Gas Pipe Connectors

Maintaining gas pipe connectors is crucial for safety and efficiency. Regular inspections are vital. Check for any signs of wear, rust, or leaks. Use soapy water to test joints. Bubble formation indicates a leak. Address these issues immediately.

Inspect your connectors monthly. Regular cleaning helps avoid buildup. Remove dust and debris to ensure a good seal. Tightening loose connectors can prevent gas escape. However, be careful not to overtighten, as this can damage the fittings.

Consider visual inspections too. Look for discoloration, which could mean a problem. Always keep the area around the connectors clear. Flammable materials near gas lines increase risk. Remember that even small oversights can lead to significant issues. Stay vigilant, and prioritize safety at all times.

Related Posts

-

2025 Guide: How to Choose the Best Gas Installers for Your Home

-

How to Choose the Best Propane Welding Torch for Your Projects

-

2025 Guide: How to Choose the Best LP Torch for Your Crafting Needs

-

Why Choose 8mm Gas Fittings for Your Home and Safety Needs

-

What is an LPG Hose Connector and How to Choose the Right One

-

Top 2025 LPG Blow Torch Uses Tips and Buying Guide