2025 Top Guide to LPG Gas Pipes and Fittings for Safe Installation and Use

In the ever-evolving world of energy solutions, the importance of safe and effective installations of LPG gas pipes and fittings cannot be overstated. As we look towards 2025, understanding the best practices for these crucial components of gas infrastructure becomes paramount. LPG gas pipes and fittings play a vital role in ensuring that liquefied petroleum gas is transported and utilized efficiently, minimizing risks associated with leaks and inefficiencies.

This guide aims to provide a comprehensive overview of the essential aspects to consider when working with LPG gas pipes and fittings. From selecting the appropriate materials to installation techniques, we will delve into the best practices that guarantee not only compliance with safety standards but also the durability and reliability of gas systems. As we navigate through the intricacies of LPG gas installations, our focus will remain on fostering a culture of safety and performance, equipping professionals and homeowners alike with the knowledge needed to handle this vital resource responsibly.

Top Trends in LPG Gas Pipe Materials and Technologies for 2025

In 2025, the trends in LPG gas pipe materials and technologies are set to significantly enhance safety and efficiency in installations. With an increasing focus on sustainability, the use of high-density polyethylene (HDPE) pipes is on the rise due to their durability and resistance to corrosion. According to the Global Gas Infrastructure Report 2023, HDPE pipes can reduce environmental impact by approximately 30% compared to traditional steel pipes. This shift not only promotes longer service life but also minimizes the potential for leaks, which is crucial for maintaining safety standards.

Additionally, advancements in smart technology for gas monitoring systems are transforming how LPG is utilized in both residential and commercial settings. Innovative sensors integrated into gas pipelines can detect leaks in real-time, providing immediate alerts to users. A recent study by the Institute of Gas Technology highlighted that such systems can reduce response times to gas leaks by up to 40%, significantly reducing the risks associated with LPG usage. These trends underscore the industry's commitment to improving safety protocols through better materials and cutting-edge technology, ensuring that LPG remains a reliable energy source for the future.

2025 Top Trends in LPG Gas Pipe Materials and Technologies

Essential Standards and Regulations for LPG Gas Pipe Installation

When it comes to the installation and use of LPG gas pipes and fittings, adhering to essential standards and regulations is paramount for ensuring safety and compliance. Various authorities and standardization organizations provide guidelines that dictate the materials, installation methods, and maintenance practices necessary for LPG systems. It is crucial to familiarize yourself with the local regulations that govern LPG installations, as they often align with national safety standards and might include specific requirements for pressure ratings and testing certifications.

Tips: Always ensure that the pipes and fittings are manufactured from approved materials that can withstand the pressures associated with LPG. When selecting components, check for proper certifications and markings that indicate compliance with safety standards. Regular inspections and maintenance are also vital; they help in identifying potential leaks or weaknesses in the system, allowing for timely repairs before any hazardous situation arises.

Another important aspect of LPG installations is the correct layout and routing of pipes. Pipes should be installed with appropriate supports and at a safe distance from heat sources. Additionally, ensure that all installations are accessible for future maintenance. Consider using signage and color coding to enhance awareness of LPG piping systems in both residential and commercial settings.

Tips: During installation, always maintain adequate ventilation in working areas, and consider using protective gear. If you're unsure about any aspect of the installation process, it’s advisable to consult with a certified professional to ensure that all regulations are properly followed.

Safety Considerations in the Use of LPG Gas Fittings

When using LPG gas fittings, safety considerations are paramount to ensuring both secure installations and safe operation. According to the National Fire Protection Association (NFPA), improper installation of gas fittings can lead to significant hazards, including gas leaks and potential fires. Statistics show that over 30% of residential gas accidents are attributed to faulty piping or fittings, making it essential to prioritize high-quality components and adhere to industry standards during installation.

To enhance safety, it is crucial to regularly inspect LPG gas lines and fittings for signs of wear, corrosion, or leaks. A simple soap solution can be applied to joints and connections; bubbling indicates a possible leak. Furthermore, ensuring proper ventilation in areas where LPG is used helps mitigate the buildup of gas in case of a leak, thereby reducing the risk of explosive hazards.

Tips:

- Always engage a certified professional for installation and maintenance of LPG piping systems.

- Keep combustible materials away from all LPG fittings and ensure access to gas shut-off valves is unobstructed.

- Invest in gas detectors that can alert occupants to any leaks, as early detection is key to preventing dangerous situations.

Comparative Analysis of LPG Pipe Sizing and Flow Rates

When considering the installation of LPG gas pipes, understanding the sizing and flow rates is crucial for ensuring safety and efficiency. Proper pipe sizing is essential, as it directly impacts the pressure drop experienced within the system. A well-sized pipe allows the LPG to flow seamlessly from the cylinder to appliances, minimizing the risk of leaks or incomplete combustion. When selecting the appropriate diameter, factors such as the length of the run, the number of bends in the pipe, and the total demand of the appliances must be carefully evaluated.

Flow rates are another pivotal aspect to consider in a safe LPG installation. Each appliance has a specific requirement for gas flow, typically measured in cubic meters per hour or kilojoules. It's important to match the total flow requirement of all connected appliances to the capacity of the piping system. An undersized pipe can lead to insufficient gas supply, resulting in poor appliance performance, while an oversized pipe may cause condensation issues, ultimately affecting safety and efficiency. Therefore, performing a comprehensive comparative analysis of different pipe sizes alongside their corresponding flow rates is vital for effective LPG systems design and installation.

2025 Top Guide to LPG Gas Pipes and Fittings for Safe Installation and Use - Comparative Analysis of LPG Pipe Sizing and Flow Rates

| Pipe Size (inches) | Nominal Diameter (mm) | Flow Rate (kg/h) | Max Pressure (bar) | Recommended Use |

|---|---|---|---|---|

| 1/2 | 15 | 25 | 5 | Home appliances |

| 3/4 | 20 | 50 | 5 | Multiple appliances |

| 1 | 25 | 100 | 5 | Commercial kitchens |

| 1 1/4 | 32 | 150 | 5 | Industrial use |

| 1 1/2 | 40 | 250 | 5 | Large scale operations |

Maintenance Best Practices for LPG Gas Pipes and Fittings

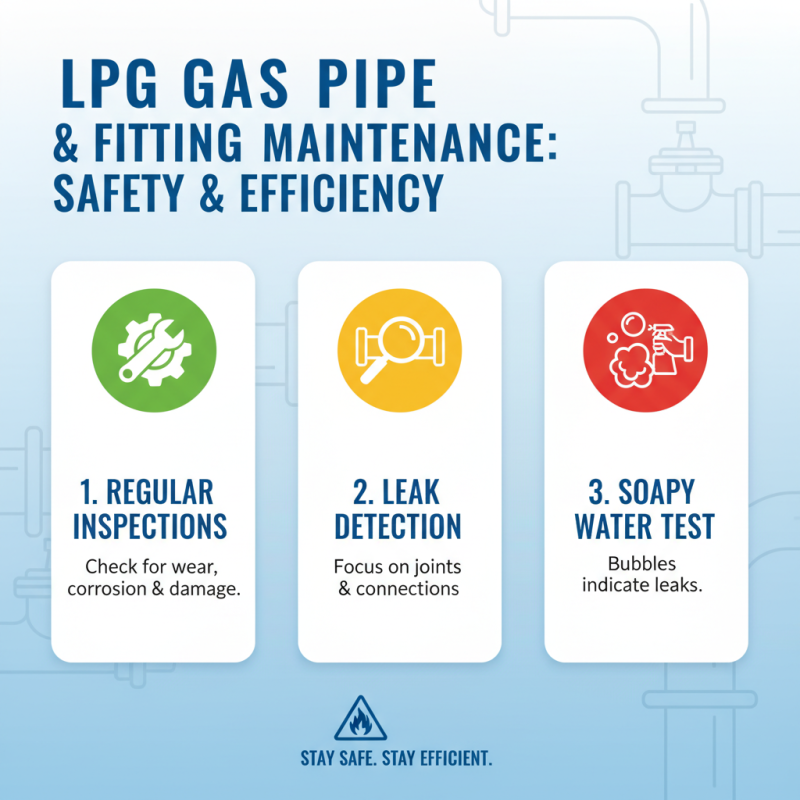

When it comes to safely installing and using LPG gas pipes and fittings, maintenance plays a crucial role in ensuring efficiency and safety. Regular inspections should be conducted to check for signs of wear, corrosion, or damage. This involves looking for any leaks, particularly at joints and connections, as these can lead to dangerous situations. Utilizing soapy water to test for leaks is a simple yet effective method; bubbles will form at any points where gas is escaping.

Furthermore, it is essential to maintain a clean environment around gas pipes and fittings. Removing any combustible materials from the vicinity of gas lines helps prevent accidental ignitions. Additionally, keeping pipes well insulated and protected from extreme weather conditions can significantly prolong their lifespan. It is advisable to follow a scheduled maintenance routine, which includes replacing any compromised fittings and ensuring that all components meet safety standards. Regular maintenance not only extends the life of LPG installations but also fosters a safer environment for everyone involved.

Related Posts

-

Why Choose 8mm Gas Fittings for Your Home and Safety Needs

-

Discovering the Benefits of a Gas Heater with Cylinder for Your Home Comfort

-

Maximize Your Comfort: The Ultimate Guide to Choosing the Right Gas Burner Heater for Your Home

-

The Ultimate Guide to Choosing the Best Gas Line Crimping Tool for Your Projects

-

2025 Top Trends in Gas Fittings for Home and Commercial Use

-

2025 How to Use LP Torch for Effective Welding and Metalwork Techniques