2025 Guide: How to Choose the Right Propane Gas Hose and Fittings

When it comes to utilizing propane for heating, cooking, or recreational purposes, the quality and suitability of your propane gas hose and fittings cannot be overlooked. As we inch closer to 2025, understanding the intricacies of selecting the right components becomes increasingly vital for safety and efficiency. The proper propane gas hose and fittings ensure a secure connection, minimizing the risk of leaks and enhancing the overall functionality of your propane-powered equipment.

In this guide, we will explore key considerations that should inform your decision-making process when choosing propane gas hose and fittings. We will delve into factors such as material compatibility, pressure ratings, and environmental considerations that affect the performance and durability of these components. Whether you're a seasoned professional or a novice user, having a solid grasp of these elements will empower you to make informed choices that prioritize safety and optimal performance in your propane applications.

Understanding Propane Gas Hoses: Types and Applications

When it comes to propane gas hoses, understanding the various types and their applications is crucial for ensuring safety and efficiency in using propane as a fuel source. There are primarily three types of propane gas hoses:

rubber,

PVC, and

stainless steel.

Rubber hoses are the most common choice, recognized for their durability and flexibility, making them suitable for high-pressure applications. PVC hoses, on the other hand, are lightweight and cost-effective, usually employed in low-pressure applications such as residential grilling or heating. Lastly, stainless steel hoses provide excellent resistance to extreme temperatures and corrosive environments, making them ideal for industrial applications.

Choosing the right hose also involves considering the fittings, which are essential for secure connections. Various fittings are designed to accommodate different hose types and sizes, ensuring a snug fit that prevents leaks. When selecting fittings, it’s important to assess the application—whether it’s for outdoor grilling, indoor heating, or industrial machinery—as each will have specific requirements. Additionally, users should look for fittings that comply with safety standards and regulations to ensure proper usage. Understanding these aspects not only enhances the performance of propane systems but also significantly increases safety during operation.

Key Factors to Consider When Choosing Propane Hose

When selecting the right propane gas hose and fittings, there are several key factors to consider that ensure safety and efficiency in your application. The American National Standards Institute (ANSI) recommends that all propane hoses should meet specific compliance standards, such as the UL 569, which outlines the requirements for hose assembly used in the transfer of propane and other liquefied petroleum gases. This compliance not only guarantees durability but also minimizes the risk of leaks, which can pose serious safety threats.

Another critical consideration is the diameter and length of the propane hose. According to the National Fire Protection Association (NFPA), a properly sized hose can significantly enhance the flow rate of gas and reduce pressure drop, which is essential for maintaining performance in various applications. For example, a hose diameter that is too small can restrict gas flow and lead to inefficient operation, whereas an excessively long hose can increase the risk of kinking and wear. Therefore, it is vital to evaluate the specific requirements of your propane system to determine the appropriate specifications that align with safety regulations and functional needs.

Additionally, environmental factors play a role in the selection of hoses and fittings. Many industry reports indicate that exposure to extreme temperatures, UV light, and chemicals can affect the performance and lifespan of propane hoses. Choosing materials designed for these conditions, such as rubber or thermoplastic elastomer options rated for outdoor use, can enhance durability. Consulting with standards and practices set by recognized organizations can guide you in making informed choices, ensuring your setup is both safe and effective.

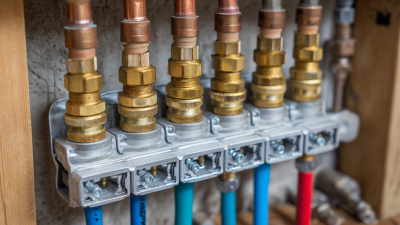

Essential Fittings for Propane Gas Connections

When setting up propane gas connections, the right fittings are crucial for safety and efficiency. Essential fittings include adapters, regulators, and quick disconnects. Adapters allow different sized hoses and connectors to join, making them versatile for various setups. Choosing the correct adapter ensures a secure fit, preventing leaks that could lead to dangerous situations. Regular inspection of these fittings is necessary to ensure they are in good condition and free of wear or damage.

Regulators play a vital role in controlling the pressure of the propane gas flowing through the system. Selecting a regulator that matches your specific needs is critical; it must handle the appropriate flow rates based on your appliances or equipment. This ensures that there is a consistent and safe supply of gas. Additionally, quick disconnect fittings are beneficial for ease of use, allowing users to disengage and reconnect hoses without tools. They contribute to the convenience of switching between appliances while maintaining high safety standards.

Safety Standards and Regulations for Propane Hoses

When choosing propane gas hoses and fittings, it's crucial to pay attention to safety standards and regulations designed to ensure safe handling and usage. Propane hoses must meet specific industry standards that dictate the materials, pressure ratings, and durability required for safe operation. The American National Standards Institute (ANSI) and Underwriters Laboratories (UL) are two organizations that set these safety standards. These guidelines help prevent leaks and potential hazards associated with propane gas misuse.

Tips: Always check the labeling on your propane hose for compliance with relevant standards. Ensure that the hose is rated for the maximum pressure you'll be using. Moreover, inspect hoses regularly for signs of wear and tear, such as cracks or fraying, and replace any damaged hoses immediately.

Another important aspect is the proper fitting for your propane system. Depending on your application, you need to choose fittings that not only comply with safety standards but also ensure a tight seal to prevent leaks. Use malleable fittings approved for propane use, as they are designed to withstand the pressures and temperatures involved in gas transfer.

Tips: When connecting fittings, apply the proper torque and use thread sealant approved for propane to enhance the joint's integrity. Regularly inspect all connection points for leaks by using soapy water; bubbles will form at any leak sites, allowing for easy identification and repair.

Maintenance Tips for Propane Gas Hoses and Fittings

When using propane gas hoses and fittings, regular maintenance is essential to ensure safety and efficiency. Over time, hoses can become brittle or develop leaks, which may pose serious risks. Therefore, periodic inspections should be performed to check for any signs of wear, cracks, or swelling. If you notice any damage, it’s vital to replace the hose immediately to prevent potential hazards.

Tips: Always store propane hoses in a cool, dry place away from direct sunlight to reduce the aging process. Additionally, consider using a hose cover to provide extra protection against environmental factors. Periodically apply a soap solution to the fittings and connection points to detect any leaks, as this is one of the most effective ways to ensure a secure system.

Another important aspect of maintenance is ensuring that all connections are tight and secure. Loose fittings can lead to gas leaks and are a common cause of accidents. Before each use, double-check that all your connections are properly tight, but be careful not to overtighten, which can also damage the fittings. Adopting these maintenance practices not only enhances safety but can also extend the lifespan of your propane accessories.

Related Posts

-

2025 Guide: How to Choose the Best Gas Installers for Your Home

-

What is an LPG Hose Connector and How to Choose the Right One

-

Understanding the Importance of Propane Shut Off Valves: Safety Tips and Best Practices

-

Top 10 Essential Gas Fitting Supplies for Every DIY Enthusiast

-

Maximizing Efficiency: The Essential Guide to Choosing the Right Gas Ball Valve for Your Needs

-

The Future of Home Heating How Gas PEX Systems Are Transforming Energy Efficiency